By Bryn Kelley, second year student, MPhil Textile Conservation.

One of the first lessons I learned regarding wet cleaning in textile conservation is the importance of considering the fibres present. This came to the fore in my second semester object this year; a 1930s-40s dress with cotton warp and viscose rayon weft from the collection of Dumfries Museum and Camera Obscura, which is believed to have been worn as an attendant’s dress in the annual Guid Nychburris pageant in Dumfries Scotland. As part of treatment, I wet cleaned this dress. The decision making was complex, as viscose rayon is weaker when wet.[1] Having now successfully completed the cleaning, I would like to share a bit about what I found particularly key in the process.

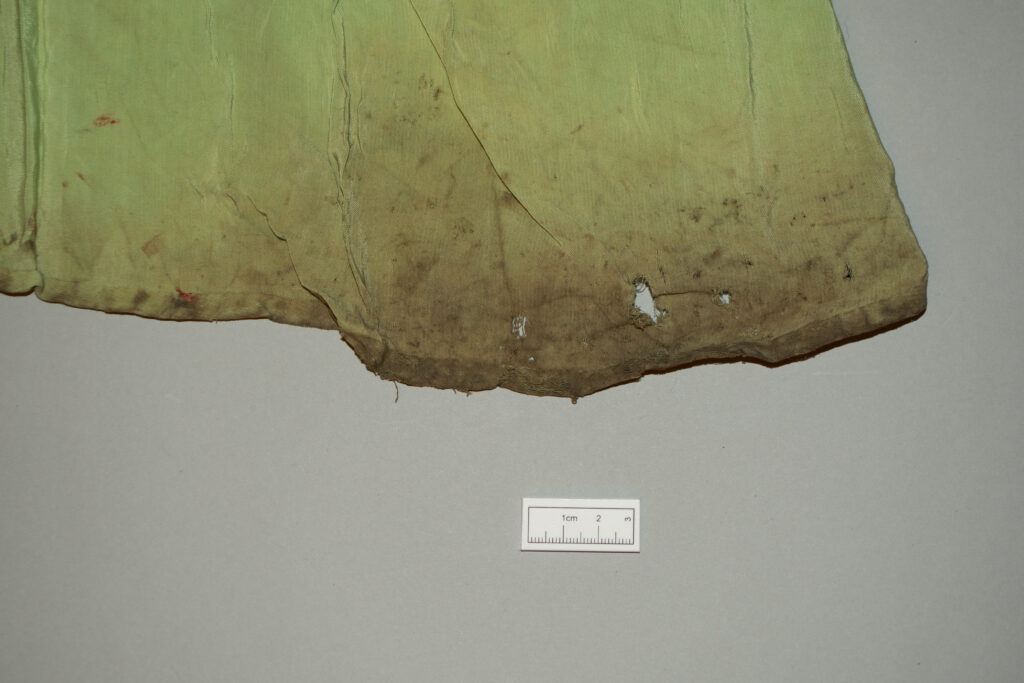

Fig.2 and 3. Soiling and creasing at the dress hem and bodice_before treatment © University of Glasgow and courtesy of Dumfries Museum and Camera Obscura. 2024.

After conducting microscopic fibre identification and ATR-FTIR spectroscopy, the warp was identified as cotton and the weft as viscose rayon for both fabrics present. Based on the reaction of viscose rayon from that period to water, wet cleaning seemed like a high-risk treatment at first consideration. However, there were other considerations as the dress was heavily soiled (Fig.2) and creased (Fig.3) and one treatment aim was to improve the visual appearance of the object. After much thought and discussion with my supervisor, client, and peers, I decided preparatory wet cleaning related testing would be a worthwhile in order to inform the final treatment decision.

The first testing I carried out was washfast testing of samples of both warps and wefts in de-ionised water and after that progressing to similar testing with the preferred washbath formula. From these tests, the only immediately discernable risk factor was dye bleed on the orange rayon which began once the fibre had been wet for at least an hour. This testing was then followed by the wetting out of a portion of a seam allowance as a way of anticipating the way the fabric might react when wet. After all this testing, the risks seemed manageable compared to the benefits of wet. With consent from the client, the non-washfast trim was removed and areas of weakness were sandwiched in nylon net to stabilize them during the cleaning. In an abundance of caution, this included very small areas of weakness that might not warrant netting on other fabrics. Similarly, a nylon net silhouette of the dress was cut and inserted between the front and back to provide additional structure while wet cleaning.

With the object prepared, the wet cleaning itself was at hand. During the wetting out process there were several areas that did not wet out the same as the rest of the object (see Fig 4). Some of these areas corresponded with the presence of staining from metal. Upon the introduction of the anionic surfactant to the wash bath (1.32 g/l Hostapon TPHC) these areas wetted out and cleaning was underway. Despite indications from testing, the dye of the orange fabric bled almost immediately, however, since I was very well prepared and had two additional people on hand to help, I was able to manage the bleeding both in the bath and during the drying process. The object was dried flat with the use of hair dryers (see Fig 3.) to limit strain caused by hanging or mounting while wet.

Having completed the treatment, I have reflected that several factors were influential in the success of this treatment.

- the robust use of net sandwiching was very beneficial and worth the time involved, all areas netted remained un-changed .

- the additional support from the net insert facilitated more efficient drying as it was easier to separate the layers of wet fabric.

- while the creases needed to be addressed afterward, the drying of the garment flat ensured the strain on the wet fabric was well controlled and was more secure than drying the object while hanging or mounted.

- that good planning and organisation are essential components of a successful wet cleaning treatment and are especially valuable for keeping calm when things don’t go quite as expected!

I am very pleased with the outcome of wet cleaning this dress and I am very grateful I got the opportunity to do in with the support of my tutors in my learning on this programme.

[1] Gamper, Charlotte , Thompson Karen, and Anita Quye. “Viscose Rayon: An Absorbing Problem. An Investigation into the Impact Conservation Wet Cleaning Treatments Have on Historic Woven Viscose Rayon.” In Conserving Modernity, The Articulation of Innovation Preprints of the 9th North American Textile Conservation Conference, San Francisco, California, November 12th – 15th, 2013., NATCC: Cd format, 2013.