by Megan Mary Creamer, first year student, MPhil Textile Conservation.

One of the most exciting ways to learn about the strength and stretch of textiles is to do mechanical (tensile) testing.. Recently at the CTC, Dr Margaret Smith, taught a theoretical and practical class to first year students on tensile testing of fabric and fibre samples. Our first session focused on relating the scientific terminology and measurement units of mechanical testing to the visual representations of these properties in graphs and charts. Using a conservation case study of materials testing on tapestries we discussed how data on a fibre’s mechanical properties such as tenacity, elasticity, and yield point can impact conservation decisions. We also carried out mechanical testing using an Instron 5544 mechanical tester. Wool yarn samples which had been hand and industrially spun were tested. This demonstrated the differences in heterogeneous and homogenous composition as the hand spun samples showed greater strength and elongation variation.

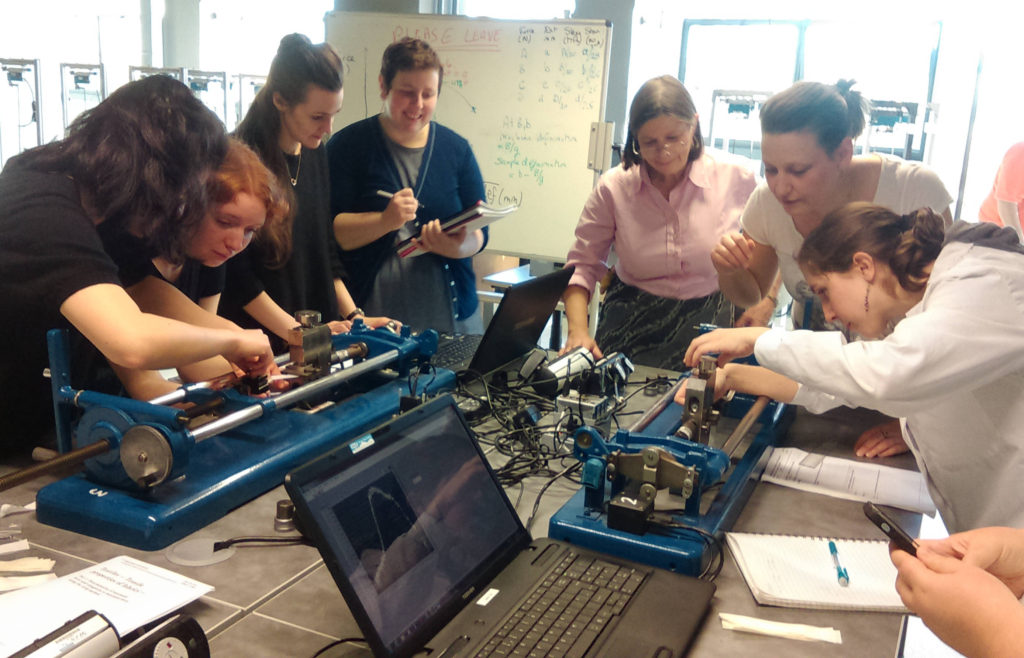

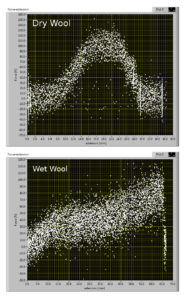

Our second session with Margaret took place with Professor Elizabeth Tanner and John Davidson in the Tuck Lab, School of Engineering, University of Glasgow. Using replicate samples of plain-weave wool, cotton, and silk, we proceeded to methodically and enthusiastically collect our data. We used hand-cranked machinery connected to a computer to slowly graph the amount of force necessary to stretch each material. Each sample was stretched past its yield points all the way to its breaking point – some ending with a satisfying snap. From our graphed data, the silk had a shorter stretch length and sharper break point. Wool, with its well-known ability to stretch, showed an extended elongation and a greater distance between the yield point and its breaking point. In the videos below, these properties are exaggerated by filming the wool testing in slow motion and the silk testing in time-lapse.

This hands-on experimentation allowed us to easily connect the graphs, relevant data points, and physical properties that we saw and heard during the mechanical testing. Below is a chart of our combined data, where you can see all the variables we tested. Each fibre type can stretch a certain amount before it breaks, and the samples can behave quite differently if they are wet or dry. The silk and cotton fibres that had been soaked in 5% v/v hydrochloric acid (HCl) or 5% v/v sodium hydroxide (NaOH), were a perfect complement to relate physical properties to the chemical properties of fibres as well. If you are interested in mechanical testing, there are many high quality, free online courses that cover the subject.

Thank you to Margaret for sharing her expertise, and for the statistical analysis of our data. Thank you also to the School of Engineering for hosting our experiment in their lab.

Best piece on wool snapping that I’ve ever read!