Authors: Charlotte Cameron, Emma Smith, Eva Maria Catic – recent graduates, MPhil Textile Conservation

An additional project for us in the second semester was the wet cleaning of a c.1930’s printed dress from our Karen Finch reference collection. The dress was to be used in a costume mounting practical undertaken by the first years, and volunteers from second year were asked to wet clean the dress prior in preparation. The dress had an overall yellow discoloration, along with more visible yellow tide lines under the arms and slight brown staining on the cuffs.

Testing

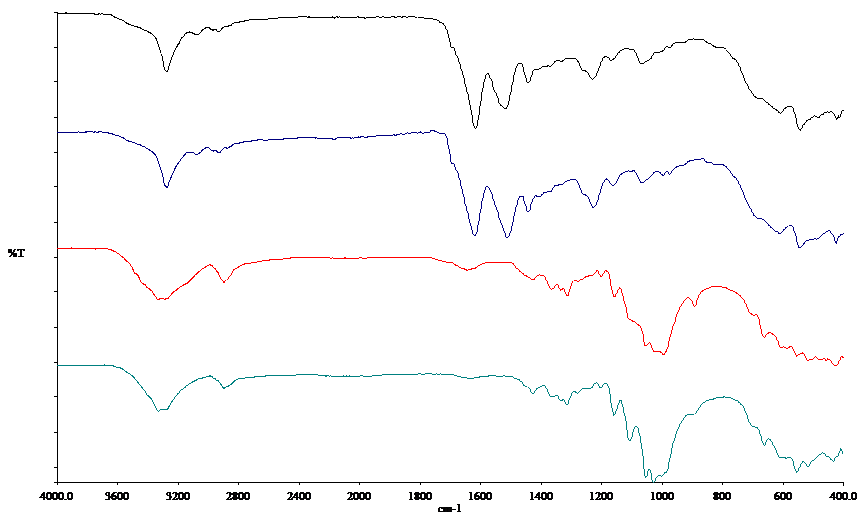

Due to the date of the dress and the visual appearance of the fabric, there was a concern it may be made of viscose rayon, an early synthetic alternative for silk which has poor wet strength and therefore implications for wet cleaning. We decided therefore to perform Fourier-transform infrared spectroscopy (FTIR) of the dress to determine material type. Unlike more conventional fibre ID using microscopy, FTIR is a non-invasive technique which did not require a sample being taken from the dress; it is also non-destructive. The technique identifies chemical bonds in a molecule, with the regenerated cellulose of viscose rayon displaying a different spectra from silk. Using this technique we were able to ascertain the dress was made of silk, alleviating our concerns about the risks of wet cleaning.

FTIR analysis:

Black line – the spectra of the dress fabric

Blue line – the spectra of a reference sample of silk fabric

Red line – the spectra of the dress thread

Green line – the spectra of a reference samples of cotton sample

As well as FTIR, we also performed in-situ wash-fastness tests on the object in order to understand how the colour of the printed design would respond to water and detergents used in wet cleaning, especially whether dye bleed may occur. Small areas of the dress were exposed to blotting paper wetted with deionized water, tap water and non-ionic and anionic conservation grade detergents. No colour bleed or transfer was seen in any of these tests and so wet cleaning went ahead.

Wet Cleaning

The dress was wet cleaned using a non-ionic detergent, Dehypon LS45®, at 3xCMC. Non-ionic detergents are easier to rinse out, and although we were no longer concerned about the poor wet strength of viscose rayon, the silk was very fine with limited handling of the dress necessary to reduce the potential for damage in wet cleaning. Non-ionic detergents also work best in slightly acidic conditions, which protein fibres also prefer.

The dress was placed in the wash bath lined with a Melinex® sheet to aid turning in wet cleaning. The dress was first ‘wetted out’ for 15 minutes in soft water, with this initial bath releasing some of the yellow discolouration. This was followed by two detergent wash baths, sponging the dress from both sides during each wash bath in order to release soiling from the fibres. The dress was then rinsed using alternate soaking and running rinses, with a final rinse in deionised water. The dress was laid flat and blotted with a cotton fabric to release excessive water and speed up drying.

Drying the Dress

After wet cleaning the dress was carried out of the bath on the Melinex sheets to a flat table, positioned on cotton muslin sheets to absorb water. During this phase of the treatment it was important that the dress be padded out from the inside to prevent new creases and fold fines appearing. Unlike a flat textile, three-dimensional costume is not normally pinned out under tension unless there are specific concerns about dimensional changes occurring as the object dries. As the dress was made of a single layer of silk this was not thought necessary, and indeed pinning under tension would likely have caused damage to the fine fabric. Nylon net was used to create rolls or ‘sausages’ which were inserted into the arms, bodice and sides of the skirt to prevent harsh lines forming during the drying. The voluminous areas of the bell sleeves and the gathers around the top of the skirt certainly benefited from this extra support. To speed up the drying process two cold fans were placed on either side of the dress.

Costume Mounting

The dress was subsequently mounted by first year students Echo Godfrey and Viviane Chen during a week of their semester which focused on costume mounting theory and practice. Echo and Viviane padded out the mannequin using polyester wadding, securing it to the calico base with herringbone stitches. Once the desired shape was achieved, a bespoke cotton jersey cover was made to cover and smooth out the padding beneath. Arms were made and inserted, and the fullness of the skirt was achieved by attaching layers of gathered net at the waist. The after treatment photographs showing the final mount help to give an understanding of how the dress was intended to be worn.

This project was a great experience for us, not only in regard to analytical analysis and wet cleaning costume, but also to work in a team and communicate each step thoroughly. We also had to balance this project with our main object treatments for the semester, increasing our time management skills in balancing multiple projects within set time-frames.

This was absolutely fascinating, especially as I remember dresses like that! Dawn Muirhead

Thank you for your article and sharing your knowledge. You have all done so well. I have a 1910 wedding gown that I am hoping to wet clean at home. I am a hobby collector of vintage dress. All the best from Jennifer – Australia